cpu dumbbell manufacturer

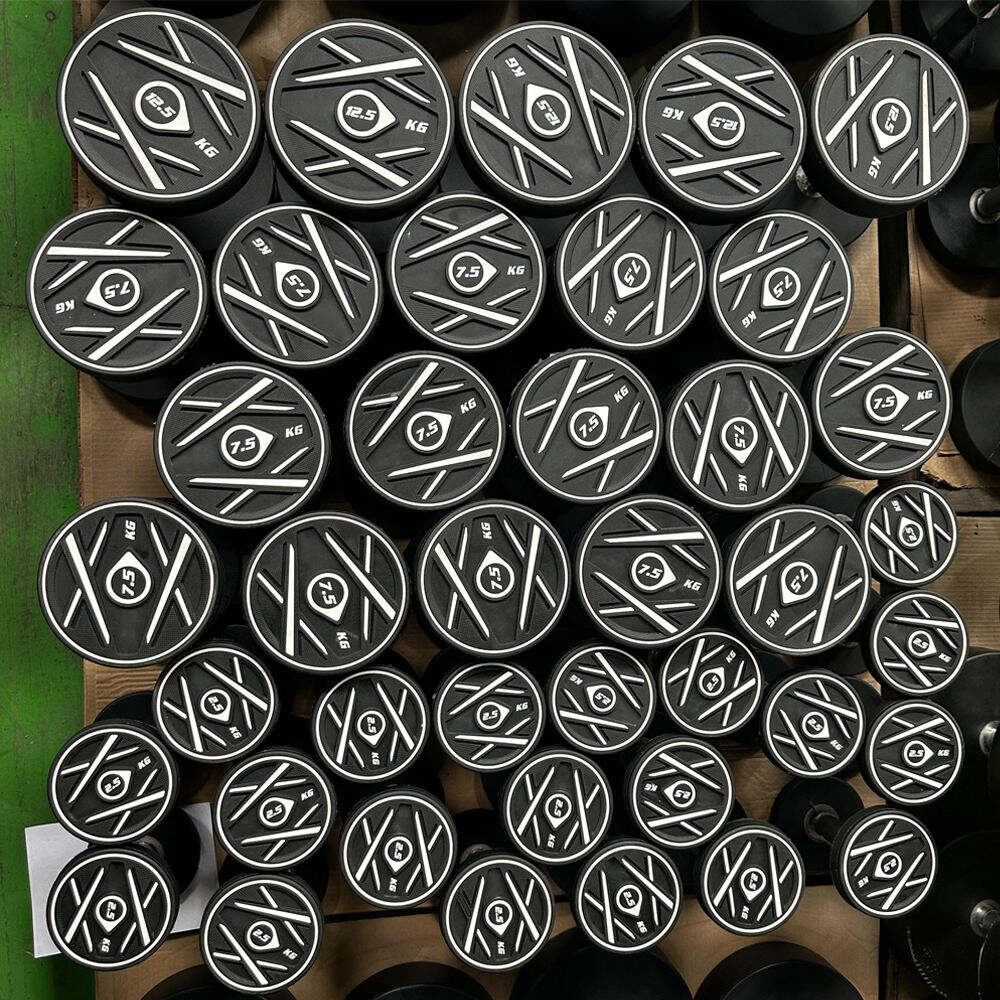

A CPU dumbbell manufacturer specializes in producing advanced fitness equipment using cutting-edge technology and precision engineering. These manufacturers employ state-of-the-art production facilities equipped with automated systems and quality control measures to create adjustable dumbbells that offer multiple weight settings in a single compact unit. The manufacturing process involves sophisticated computer-controlled machinery that ensures exact specifications for each component, from the weight plates to the selection mechanism. These facilities typically incorporate advanced materials science, utilizing high-grade steel, durable plastics, and specialized coatings to enhance product longevity. The manufacturing process includes rigorous testing phases, where each unit undergoes stress testing, durability assessments, and safety evaluations. Modern CPU dumbbell manufacturers also integrate smart technologies, such as digital weight displays and electronic weight selection systems, making their products more user-friendly and precise. Their production capabilities often extend to customization options, allowing for various weight ranges and handle designs to suit different user preferences and fitness levels.