olympic bar factory

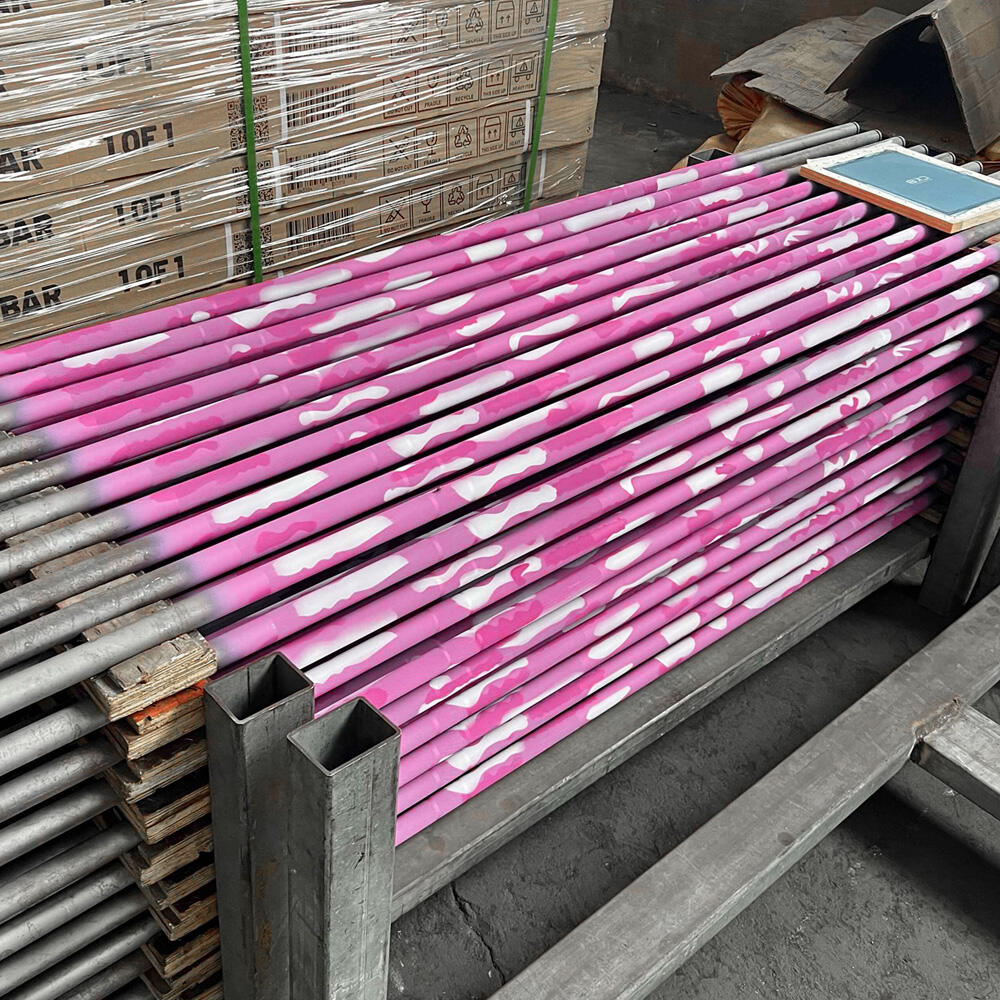

An Olympic bar factory represents a state-of-the-art manufacturing facility dedicated to producing premium quality weightlifting bars that meet International Weightlifting Federation standards. These specialized facilities combine advanced metallurgy, precise engineering, and rigorous quality control processes to create bars that withstand intense training and competition demands. The factory utilizes sophisticated machinery for cutting, turning, and knurling processes, ensuring each bar meets exact specifications for diameter, length, and weight distribution. Modern Olympic bar factories incorporate automated testing equipment to verify tensile strength, spin, and whip characteristics. The manufacturing process includes multiple stages, from raw material selection through heat treatment, plating, and final assembly. Advanced coating technologies are applied to enhance durability and corrosion resistance, while specialized knurling patterns are precisely machined to provide optimal grip. Quality control measures include load testing, straightness verification, and sleeve rotation assessment. These facilities often maintain climate-controlled environments to ensure consistent manufacturing conditions and employ certified technicians who oversee each production phase. The factory's output undergoes rigorous testing to meet international competition standards, including weight tolerance within 15 grams and precise knurling patterns for various lift types.