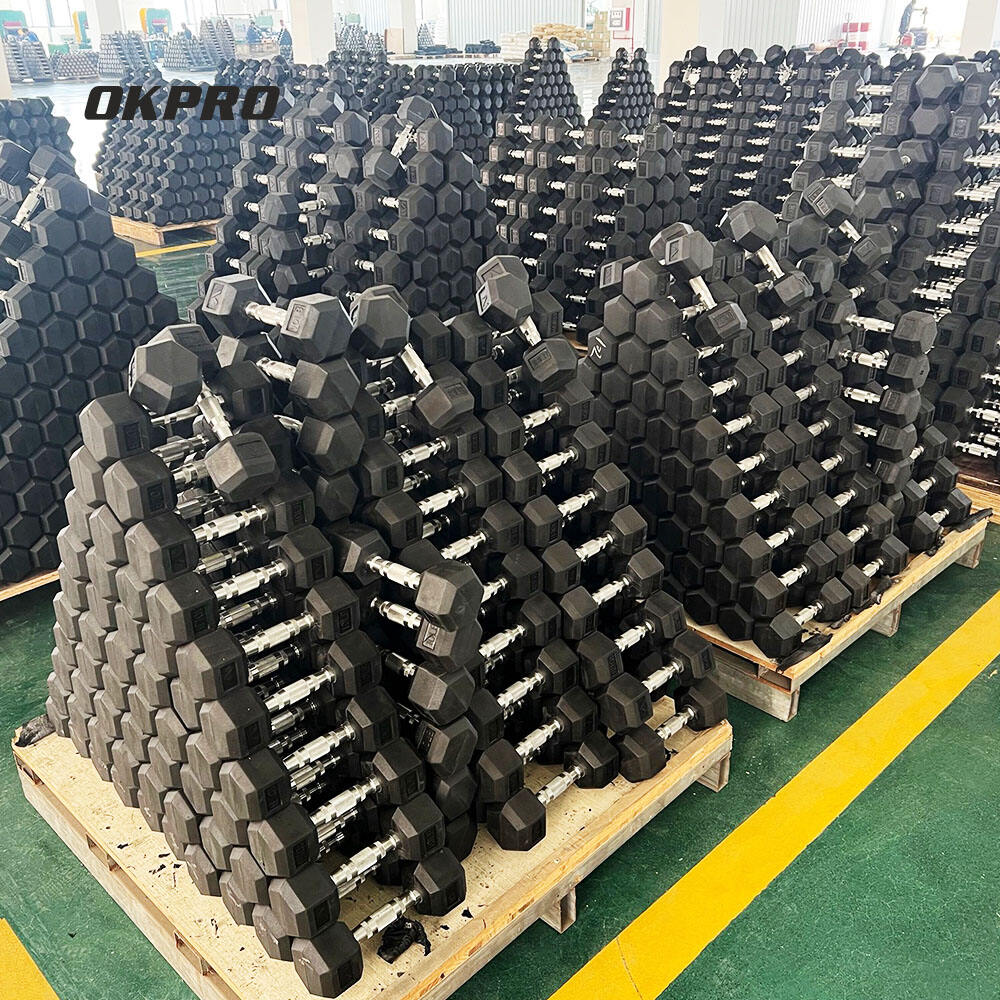

hex dumbbell factory

A hex dumbbell factory represents a state-of-the-art manufacturing facility dedicated to producing premium quality hexagonal dumbbells for fitness enthusiasts and professional athletes alike. The facility incorporates advanced casting technologies and automated production lines that ensure precise weight measurements and superior finish quality. The manufacturing process begins with the careful selection of raw materials, primarily high-grade iron and steel, which are melted and poured into specialized hexagonal molds. These molds are designed with exact specifications to prevent rolling and ensure stability during use. The factory utilizes robotic systems for consistent quality control, automated powder coating processes for durability, and advanced weight calibration equipment to maintain accuracy within strict tolerances. Each production line is equipped with modern material handling systems, thermal treatment facilities, and quality testing stations. The factory's capabilities extend to producing a wide range of weights, typically from 1 to 150 pounds, with custom options available for specific market demands. Environmental considerations are integrated into the manufacturing process, with efficient energy management systems and waste reduction protocols in place.